Industry studies and surveys

With the "Software Drives 2030" series of studies, you will learn how management decision-makers assess how changes in the automotive world affect E/E development. The "State of Practice" industry barometer asks users from development projects how to deal with current challenges.

SOFTWARE DRIVES 2030

Software Drives 2030 is a series of studies looking at the software skills a company will require to succeed in the automotive industry in the future. These studies are based on in-depth interviews with experts and decision-makers in the automotive, IT and telecommunications sectors. Their responses were summarised to provide an overall picture. The 2017 report examines required key competences, whereas the 2015 report looks at new requirements in electrical/electronics development if software evolves into the dominant driver of innovation and brand differentiation.

Software Drives 2030 was the result of partnerships with key players in industry and research.

DIGITAL CAPABILITIES FOR AUTOMOTIVE INNOVATORS 2030. STUDY REPORT, 2017

What capabilities do suppliers need to cope with digital transformation in the automotive industry? This is the central question examined by this report, which was published in the summer of 2017 as part of the Software Drives series.

Digital transformation and networking are now in full swing in automotive industry. Programmes have been introduced to make changes on all fronts, from key digital projects to experiments with service-dominated business models. The shift towards service-driven business models is challenging how entire companies and systems are organised, yet succeeding as a service provider revolves around different principles compared to businesses that merely supply products.

As a result, digital transformation with respect to automobiles is a completely new challenge for the industry. As well as changing technology paradigms, it also changes factors relating to the underlying business logic, models, setups and workflows. This report – based on a management survey looking at ‘Software Drives. Digital Capabilities for Automotive Innovators 2030’ – shows how producers and suppliers will need to reorganise themselves in order to cope with digital transformation.

THE CONSEQUENCES OF THE SHIFT TOWARDS SERVICE ORIENTATION

- Digital services are delivered in real time.

Services need to be kept up to date at every stage of the usage cycle. As a result, operations become a core function of a business, with a direct influence on competitive differentiation. - Thinking about the last start of production before the next start of production

Service orientation is resulting in an erosion of the demarcation lines between project-driven development and production. This is because functions have to be redeveloped or even reinvented during the usage cycle. - Retail is about the detail

Digital services are driven by their own business logic. On the one hand, they generate minimal margins and on the other, the functions they fulfil have to match the requirements of a specific location. This logic has to be taken into account in a variety of ways, from your initial business model to the point of implementation.

Download

Click below to download the free report on the industry study looking at »Software Drives. Digital Capabilities for Automotive Innovators 2030«.

AUTOMOTIVE E/E DEVELOPMENT 2030. STUDY REPORT, 2015

The first report in the management series on Software Drives. Automotive E/E Development 2030 was published in June 2015. This study was based on 40 interviews with experts working as key decision-makers in the automotive, IT and telecommunications sectors. An online survey was also conducted. The report illustrates how connected software will change the nature of the automotive industry.

How will the industry change?

The main questions examined in this study revolve around emerging technologies, business models, collaboration, the influence of top executives, life cycles and factors such as speed and cost-effective development.

Fundamental developments

For example, decision-makers believe they can gain clear competitive advantage by adopting service-based business models. With digital business models, payment flows shift from the point of purchase to the moment of service delivery. As a result, after-markets become main markets. In technological terms, connected layers become an interface with providers involved in value delivery, so they become more important than the traditional ‘big four’ (vehicle body, electronics, chassis and drive). In addition, existing systems are continually being overhauled and therefore supersede the current focus on start of production (SOP), model refinements and end of production (EOP).

The future of electrical/electronics development

Previously, it was the manufacturers who held responsibility for ongoing vehicle developments. Will that still be case in the future or are we about to witness a paradigm shift? In the future, an essential share of customer benefit will be delivered through services. Conventional mobility needs will merge with web-based services and form integrated offerings based on new business models. We have examined the impacts this transformation will have on electrical/electronics organisations.

Download

Click below to download the free report on the industry study looking at »Software Drives. Automotive Development 2030«.

Automotive Cybersecurity. State of Practice

Together with experts from leading car makers and suppliers, Kugler Maag Cie conducted qualitative interviews to discuss the current state of cybersecurity in the automotive industry – and how existing gaps can be closed in a methodical and structured way.

In addition, the experts informed us about the current need for practical support to help those involved in the projects to understand and apply cybersecurity tasks. Automotive Cybersecurity. State of Practice builds directly on these evaluations. The report is aimed at users who face the day-to-day challenge of implementing cybersecurity requirements in line with their project goals.

Primarily, practitioners still see cybersecurity purely in terms of technological protection. This is, however, only half the story. In fact, security requires continuous effort, from the initial concept of a connected vehicle to its scrapping.

Based on intensive interviews with experts, we provide an overview of the impact of security requirements and how they can be implemented at both organizational and project level.

HIGHLIGHTS of the 2020 CYBERSECURITY REPORT

In addition to the insights gained from the qualitative expert interviews, we have attempted to provide answers to guide those new to cybersecurity.

From the content

- Fundamentals of automotive cybersecurity

- Introduction to the world of standards

- From theory to TARA

- Architecture sketch for software updates

- Automotive SPICE in the context of cybersecurity

- Functional safety and cybersecurity

- Open questions of automotive cybersecurity

Having questions on our research program, publications, videos or events? I will gladly support you with the information you need.

Dominik Strube Public Relations and Research

Download Report

Get your copy of the industry barometer report »Automotive Cybersecurity. State of Practice 2030« here for free.

»Automotive FLOSS. State of Practice«

Together with experts from leading automotive manufacturers and suppliers, as well as from other embedded industries, Kugler Maag Cie conducted qualitative interviews to discuss the intent and extent to which open source: free, libre and open source software, is now being used in car development.

This was motivated by an elephant in the room: In external communication, companies emphasize how essential open source projects are. What's more, the open source approach seems to be the perfect answer to reducing complexity in the connected car with new, server-like vehicle architectures.

In practice, however: disillusionment. We have investigated the contradiction with the industry barometer "Automotive FLOSS. State of Practice" to get to the bottom of this paradox. What is the actual state of the open source application, and what potential do the experts surveyed see for FLOSS in the automotive industry?

Download Report

The report on the industry barometer FLOSS Automotive. State of Practice 2021 can be downloaded here free of charge.

Agile Automotive. State of Practice

AGILE IN AUTOMOTIVE. STATE OF PRACTICE 2021

Five years after the hype. In the meantime, most car makers and suppliers have gained first-hand experience in the use of agile methods, and numerous initiatives have been launched. How have agile approaches changed the work in development units, in which engineering disciplines have agile approaches been able to establish themselves?

Agile approaches found their way into many areas, in software development, but also in hardware and mechanics. From individual pilots in courageous teams, there are now companies that are testing agile approaches up to the portfolio level. Agility in the supply chain is now an intensely debated topic on the agenda as well.

The users surveyed still perceive corporate culture (70%) as a major threshold: lack of management support (46%) or little willingness to try out new things (65%).

Surprising: The majority of even experienced agilists still do not believe that agile approaches can be combined with Automotive SPICE®, functional safety or even cybersecurity. To counter these prejudices, we have dedicated a detailed chapter to the integration of agile approaches with these regulations: Yes, you can.

To read the report on the »Agile Automotive State of Practice 2021« industry barometer you can download the PDF here free of charge.

Scrum – the method of choice? Certainly not. Automotive companies and their suppliers now use a whole range of agile development processes. They consider the entire spectrum of agile options and consciously pick the processes and methods that are most likely to work in any given situation. We know this from a survey we conducted called Agile Automotive. State of Practice.

Agility has been a huge success in the automotive industry. Yet not long ago, agile development processes, methods and practices were dismissed in regulated vehicle development. But in the meantime, the industry has to a certain extent matured in its ability to pick the right agile methods. In addition to classic methods such as Scrum and Kanban, the proponents of agile practices now consciously pick the development method that is most likely to work for them.

AGILE DEVELOPMENT PROCESSES AND METHODS USED IN PRACTICE

- 79%: Scrum (down 16% vs. 2014)

- 64%: Continuous integration (+8%)

- 55%: Kanban (+16%)

- 24%: Test-driven development (+4%)

- 21%: Feature-driven development (+1%)

- 7%: Extreme programming (+1%)

- 7%: ScrumBan (+1%)

In 2014, Scrum stood on top of the agile pedestal. Other processes and methods are now quickly catching up. Kanban and continuous integration (CI) have made significant progress.

THIS IS WHY KANBAN IS ON THE RISE

- Kanban is easier to adapt than methods like Scrum. Because Kanban is an evolutionary process, it builds on existing processes, roles and responsibilities. There is no need to intervene in organisational structures or workflows.

- One particular strength of Kanban lies in maintenance and support.

More and more users are beginning to realise that Kanban does more than graph or visualise project management. As a result, Kanban principles are now being followed more strictly (one example: stringent demarcations between the activities that teams or team members are supposed to carry out at the same time).

“Kanban is always a suitable choice if the emphasis needs to be placed on workflows,” says study coordinator Sergej Weber, describing the background. “For example, when you’re troubleshooting, an event is triggered when an error is detected. A ticket is set up for this, prioritised and managed on the Kanban board. It’s different with ongoing developments of a product, when an iterative approach would be recommended using Scrum as an agile project management framework.”

Most agile projects have something to do with software development. That said, the picture was different last year: in 2014, agile methods were also applied to requirement assessments and systems design. There was a 50% drop with requirement assessments.

The dramatic drop on the left-hand side of the V-Model (the German project management methodology) contrasts directly to the right-hand side: more and more emphasis is being placed on the demand for automated testing. This is also reflected in the clear rise in methods such as continuous development and test-driven development.

THIS INFORMATION CAME FROM THE FOLLOWING INTERVIEWEES

- Heads of development: 31%

- Project managers: 46%

- Quality assurance officers: 23%

In total, 42 experts were surveyed.

Click here to download the free report on the »Agile in Automotive. State of Practice 2015« industry barometer.

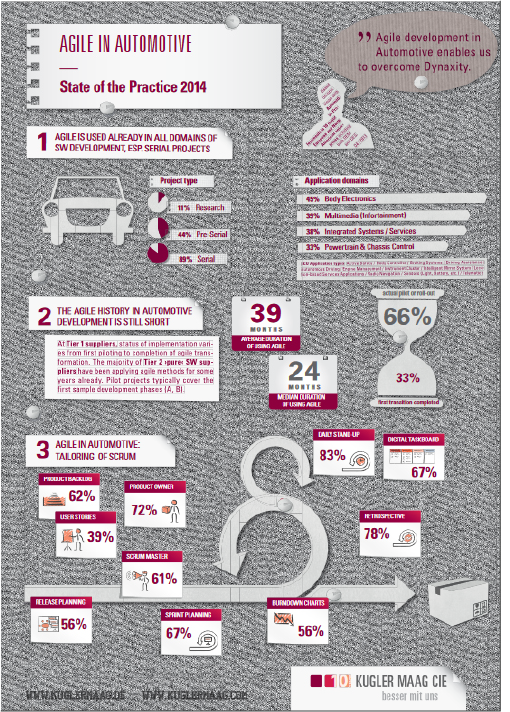

Agile in Automotive. State of Practice 2014

State of Practice 2014, our survey on agile methodology in the automotive industry, found that more and more people are turning to agile methods and practices. After initial successes, on average the surveyed manufacturers and suppliers started using agile methods like Scrum, XP and Kanban in the second half of 2011. Their aim was to make development processes more efficient and manage complexity.

“It’s different in the automotive industry. Agile methods don’t work here.” This was a widely held opinion, but a myth. This recent industry survey – Agile in Automotive. State of Practice – exposed such statements as an excuse. According to the survey of managers working for OEMs and leading suppliers, on average agile development methods have already been in use for 39 months. One third of companies have already completed roll-out and piloting.

The survey respondents included managers from Germany and the USA with responsibility for distributed development projects in Eastern Europe and Southeast Asia.

THIS INFORMATION CAME FROM THE FOLLOWING INTERVIEWEES

- Heads of development: 41%

- Project managers: 32%

- Quality assurance officers: 27%

Software development remains a key area for agile methods in the automobile industry. When asked what they mean by agile methods, many users point to Scrum as a project management framework and Kanban as a process management technique. Feature-driven development and XP are also mentioned. Methods such as daily stand-ups (83%), retrospectives and continuous integration (72%) are also applied, and one fifth of respondents use pair programming.

AGILE ON MANY FRONTS

It was surprising to find that agile methods have become more popular in serial production (89%) rather than research. The respondents are much less likely to use Scrum or Kanban in pilot production (pre-series) or R&D (44% and 11% respectively). These methods are used for all kinds of control units, and equally in the development of braking units and driver assistance systems.

EXAMPLES OF APPLICATIONS

- Vehicle electronics 45%

- Multimedia applications 39%

- Connectivity and integrated services 38%

- Power train controls 33%

INDIVIDUAL ADAPTATIONS HAVE BECOME THE RULE

People working in everyday vehicle development are willing to adapt agile methods to their specific requirements. This is best seen by looking at what they do with Scrum: 83% of users organise daily stand-ups, but only 39% employ user stories. Just under two thirds of the surveyed companies use Scrum Masters to support agile teams.

Key factors when introducing agile methods are backing from management, communication and being given the freedom to try out new things.

USERS WELCOME FLEXIBILITY

People working in this area want to shorten product development cycles. The traditional approach involving sequential development has proven to be insufficiently flexible for managing complexity.

The pioneers of agile thinking were rewarded for their efforts with enhanced productivity and more satisfied teams. Their methods also raised the profile of team members and achievements within the organisation. As communication improved, teams were not just able to do good things, but also talk about those good things.

Click here to download the free poster that goes with the »Agile in Automotive. State of Practice 2014« industry barometer.